Popular searches:

Ishikawa, Exhibitions, Events

Return to list page

2025/06/20

Ishikawa Company practices its environmental protection mission through technological innovation. The independently developed slag and scrap iron magnetic separation recycling equipment has been officially put into operation, achieving an iron resource recovery rate of over 97% from casting waste slag and reducing waste by thousands of tons annually.

As a manufacturing enterprise, we are acutely aware of the challenges in slag treatment during the production process. In traditional methods, the daily generated slag not only occupies a large amount of space but also incurs high waste disposal costs. More crucially, these slags contain untapped metallic resources!

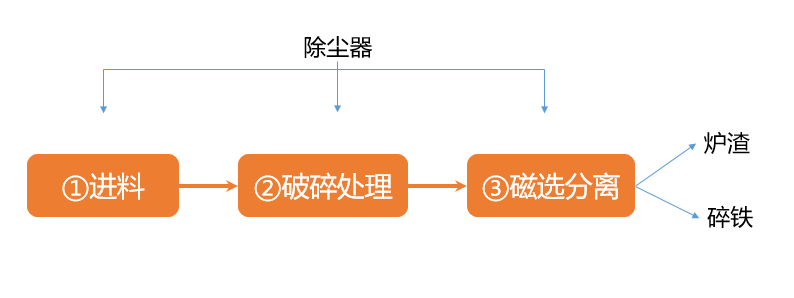

Through independent research and development by the Siim Equipment Division team, the device efficiently recycles 1 ton of scrap iron from slag daily via a process chain of crushing—magnetic separation—separation, achieving "comprehensive utilization" of resources.

High-efficiency Crushing

Adopts a multi-stage crushing system to decompose slag into particles below 10mm, releasing the metal

Magnetic Separation

Equipped with a strong magnetic drum (magnetic field intensity ≥5,000 Gauss), achieving an iron recovery rate of over 97%.

Intelligent Control

Integrates a PLC automation system to realize unmanned intervention in the entire process of crushing-magnetic separation-sorting.

Every transformation of slag is a guardianship of our planet.

Each slag conversion embodies the practice of the "reduction, recycling, harmlessness" philosophy, building a green defense for the Earth.

Through intelligent crushing and high-precision magnetic separation, the vast majority of metals are accurately extracted. 1 ton of scrap iron returns to the production chain, reducing the damage to mountains and rivers caused by iron ore mining.

Recycling 1 ton of scrap iron is equivalent to reducing 1.5 tons of carbon emissions. The daily slag treatment volume plants tens of thousands of "invisible green trees" for the Earth year after year.

The slag and scrap iron recycling equipment effectively separates metal components in slag, improving resource recovery rate, reducing waste volume, and lowering subsequent treatment costs. In addition, residual slag can be used as building material raw materials to maximize resource utilization.

Suzhou Ishikawa has achieved triple breakthroughs of "solid waste reduction-resource regeneration-cost optimization" through equipment technology innovation, continuously exploring the infinite possibilities of green manufacturing, and setting a benchmark for sustainable development in the industry!

In the new working environment, we will continue to uphold the core concepts of pragmatism and innovation, and is committed to providing customers with more excellent products and services...

Each invention patent bears our persistent pursuit of technological progress and our beautiful vision for the future.

There is only one core goal: to ensure that the casting products you ordered are delivered to you faster, more accurately, and more stably!